HS41X Anti-Pollution Isolating Check Valve

- Model

- HS41X

Item specifics

- Nominal Pressure

- 1.0-1.6MPa

- Suitable Medium

- Water, oil and other non-corrosive liquid

- Medium Temperature

- 0-80℃

- Test Standard

- GB/T13927-1992

Review

Description

Brief Introduction

HS41X Anti-Pollution Isolating valve/ Check Valve is a valve which is installed in various kinds pipeline system to strictly stop media back flow, to protect the media and device of downstream from pollution.It is composed of two series-wound check valves and connecting parts. seal strictly to ensure media no back flow. it is reliable and with long service life.

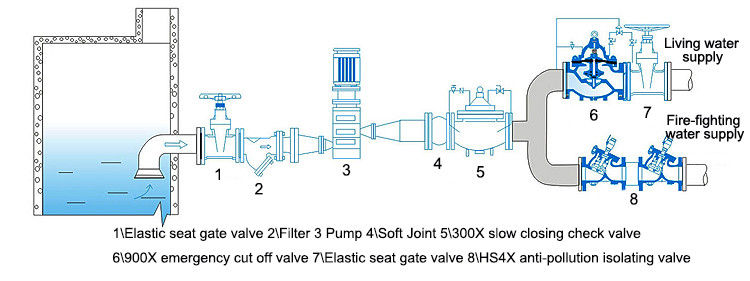

Anti-pollution isolating valve Installed in all kinds of piping system to strictly prevent backflow medium, protect by medium or device from pollution of non-return valve. Consists of two series of check valve and transition sections, sealed tight, to ensure that the media there is no point return. Pipeline anti-pollution isolating valve is used to prevent backflow pollution in drinking water pipeline safety devices, to ensure the health and safety of drinking water. The structure of the product: secure anti-pollution isolating valve is between the two check valves and a drainage device.Drainer on cavity with high-pressure hose connected to the level of the check valve inlet side. The first, second level check valve is mainly composed of valve body, valve cover, valve, gasket, spring, etc. Drainage device is mainly composed of valve body, valve cover, diaphragm, disc, seal plate, valve core, valve seat, spring, etc. Ordinary anti-pollution isolating valve for the two check valves in series. Working principle: anti-pollution isolating valve for the two check valves series, when there is a seal damage, the other one also plays a role of sealing, to prevent backflow. But after two check valve seal damage at the same time, lose the check, its safety and reliability is relatively worse, principle of work is relatively simple. Anti-pollution isolating valve on the basis of normal middle add drainer, so even if the two check valve seal damage at the same time, it also can have the effect of preventing backflow pollution.

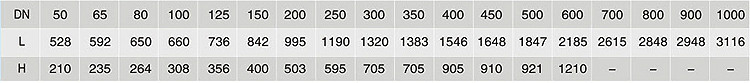

Specification

Nominal Pressure | 1.0-1.6 MPa |

Nominal Diameter | 50-1000mm |

Suitable Media | Water, oil and other non-corrosive media |

Suitable Temperature | 0-80℃ |

Test Standard | GB/T 13927-1992 |

Main Material

Valve Body, Valve Deck, Disc | Spring | Draining Valve |

Gray Cast iron, Ductile Iron, Cast Steel, | Spring steel, Stainless steel | Cast steel, Stainless steel |

Installation

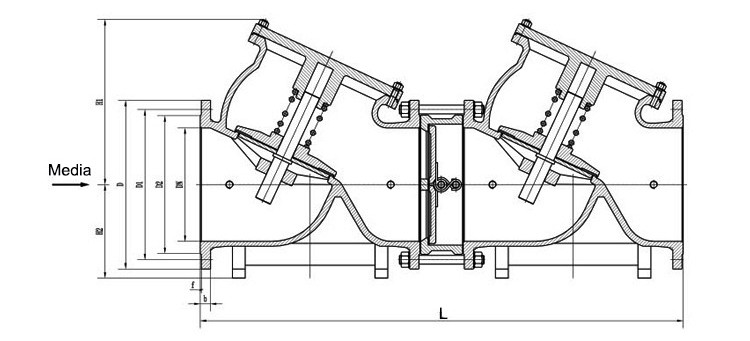

Dimension