Galvanized Steel Flexible Conduit (P3 Type)

- Model

- SLD

Item specifics

- Feature

- High tensile, strong vandalism

- Available Sizes

- 3/8

- Conduit barrier temperature

- -10°-70°

Review

Description

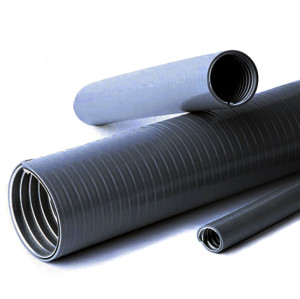

Galvanized Steel Flexible Conduit (P3 Type)

We provide a comprehensive range of Galvanized Steel Flexible Conduit, which is designed in order to provide mechanical strength and higher flexibility. These helically wound flexible conduits in galvanized steel are appreciated for features such as corrosion resistance, durability, and high functional life. We offer these conduits in natural as well as in zinc finish.

Galvanized Steel Flexible Conduit Features:

Corrugated Bare Metal Conduits are highly flexible and have an angular profile. Their robust construction makes them resistant to high mechanical stresses. These also have high impact resistance. These conduits offer IP54 protection when combined with appropriate Controlwell conduit glands.

1. Superior flexible, smooth, easy for installation and position. The smooth internal surface, easy to pull wire through, various assorted fittings for convenient installation.

2. High tensile resistant, strong vandalism resistant and strong corrosion resistant, Temperature-resistant, resistant to high temperature chips.

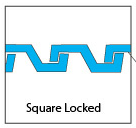

3. Turn-over locked structure to increase strength resistant, hard to break or distort.

4. Reasonable construction, stable performance and superior electrical performance.

5. Can be installed directly, do not need preset tube or wire.

6. Can add PVC coating or wire braiding on the flexible metal conduit to achieve function of waterproof and explosion proof, also supply various connectors and junction boxes for the option of customers.

Application Areas:

Bathroomfittings and interiors

Areassubject to heat and sparks (foundries, welding, etc)

Used asmechanical protection for insulated electrical cables and wires that arefunctional in normal atmospheric temperature

Under floorapplications for computer/floor boxes

Forfurnace/oven applications

Used for connecting machines to controls

Specifications:

Highmechanical strength

Highlyflexible

Temperaturerange: -100°C to +300°C

IP rating:IP40 with standard fittings

Inherent low fire hazard product

Specification 1:

Cat.# | Size | Internal Diameter (mm) | External Diameter (mm) | Min. Bend Radiuce (mm) | Coil Packing (m) |

JS-101 | 3/8" | 10 | 13 | 30 | 50 |

JS-102 | 1/2" | 13 | 17 | 30 | 50 |

JS-103 | 5/8" | 16 | 19 | 43 | 50 |

JS-104 | 3/4" | 19 | 23 | 50 | 50 |

JS-105 | 1” | 25 | 29 | 57 | 50 |

JS-106 | 1¼" | 32 | 36 | 70 | 50 |

JS-107 | 1½" | 38 | 43 | 80 | 25 |

JS-108 | 2" | 50 | 55 | 95 | 25 |

JS-109 | 2½"" | 63 | 70 | 140 | 15 |

JS-110 | 3" | 78 | 85 | 150 | 10 |

JS-111 | 4" | 101 | 109 | 190 | 10 |

Cat.# | Size | Internal Diameter (mm) | External Diameter (mm) | Min. Bend Radiuce (mm) | Coil Packing (m) |

JS-016 | 16 mm | 10 | 13 | 30 | 50 |

JS-020 | 20 mm | 17 | 20 | 30 | 25 |

JS-025 | 25 mm | 21 | 24 | 43 | 25 |

JS-032 | 32 mm | 28 | 32 | 50 | 20 |

JS-040 | 40 mm | 35 | 40 | 57 | 15 |

JS-050 | 50 mm | 45 | 50 | 70 | 10 |

Cat.# | Size | Internal Diameter Min. / Max. | External Diameter Min. / Max. | Min. Bend Radiuce (mm) | Coil Packing (m) |

JS-PG7 | PG7 | 9.2/9.5 | 12.6/12.9 | 30 | 50 |

JS-PG 9 | PG 9 | 10.6/10.9 | 14.0/14.3 | 35 | 50 |

JS-PG11 | PG11 | 13.6/13.9 | 16.8/17.1 | 38 | 50 |

JS-PG13 | PG13 | 15.6/15.9 | 19.5/19.8 | 40 | 50 |

JS-PG16 | PG16 | 17.3/17.6 | 21.4/21.7 | 45 | 50 |

JS-PG21 | PG21 | 22.7/27.6 | 27.3/27.6 | 50 | 25 |

JS-PG29 | PG29 | 30.8/31.2 | 35.9/36.2 | 58 | 25 |

JS-PG36 | PG36 | 39.5/39.9 | 46.0/46.2 | 90 | 25 |

JS-PG48 | PG48 | 51.0/51.4 | 57.4/57.8 | 100 | 25 |