Electric Stem Double Parallel Disc Gate Valve

Description

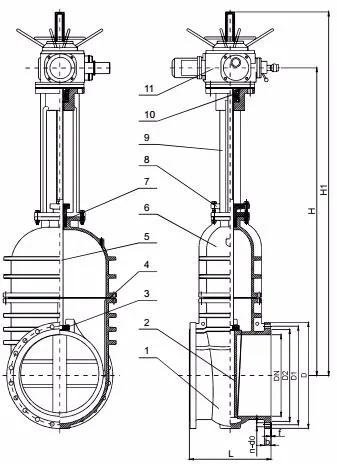

Electric Stem Double Parallel Disc Gate Valve

Application:

Widely used in water supply and drainage, gas, electricity, metallurgy, petroleum, chemical, textile and urban construction and other industries, as a device for opening and closing for steam, water, oil, pipeline.

Feature:

1. Gate valve is one of the most commonly used shut-off valve, mainly used to connect or cut off the medium in pipeline; the applicable pressure, temperature and nominal diameter range is large, especially suitable for middle and larger diameter pipes.

2. Rising stem gate valve’s stem drives up and down together with the disc, the stem transmission thread is on the outside of the valve body, therefore, user could judge the disc opening and closing or position according to the stem moving direction and position, and the transmission thread is easy to lubricate and free from fluid corrosion, but it requires a larger installation space.

3. Wedge rigid single disc gate valve structure is simple, size is small , reliable to use, it is suitable for various room temperature and middle temperature medium and pressure working condition.

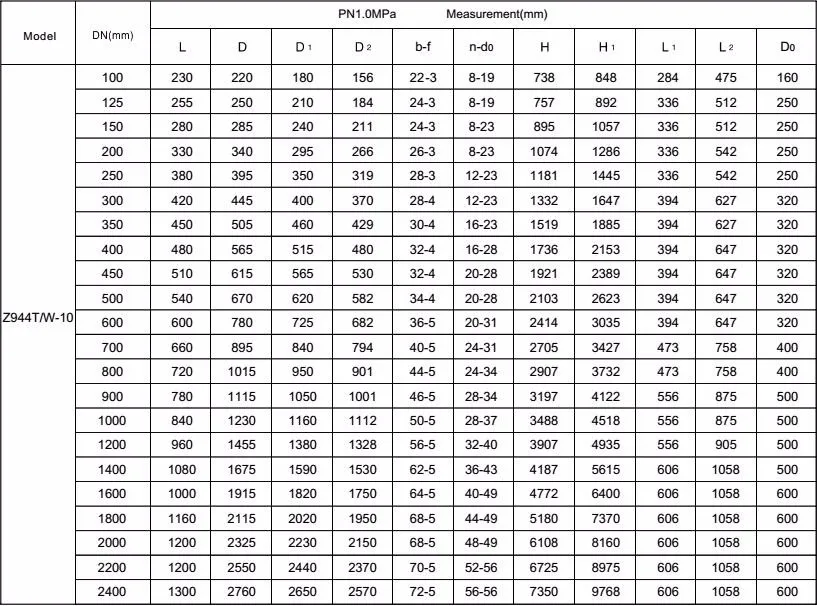

Dimension Connection Size

Design and Manufacture: GB/T12232-2005 End flange dimension GB/T17241.6-1998 Face to Face Dimension GB/T12221-2005 Test Inspection GB/T13927-2008