This valve is used in systems where bi-direction seal is required. When the valve is closed,the medium can be cut off reliably, so that the two-way zero leakage.Particularly suitable for the following work environment:

1, Water system which requires strict bi-directionclosing.

2, Medium which contains a lot of dust, sediment,weeds, garbage and other dirt

3, Working environment with high flow rate ishigh, easy to produce cavitation damage

4, Can be used as water seal ball valve for blastfurnace gas and other systems, play the role of goggle valve and slide valve

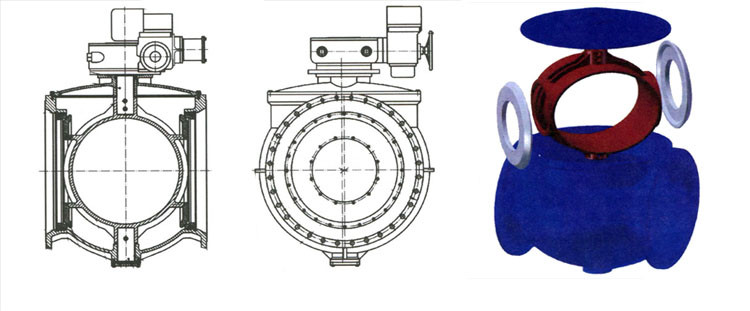

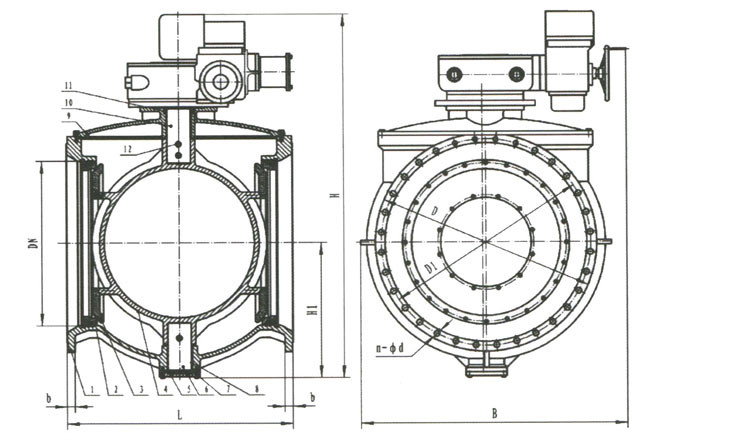

1.Built with two sets eccentric sealing surface

When the valve is closed, the pressure components on the valve plate will produce elastic deformation under the action of fluid pressure. Valve design principle is that generally direct the deformation direction to the sealing direction, that is, the greater pressure of the fluid is, the greater sealing pressure ratio is, the tighter the valve seals. If the valve is subjected to a reverse pressure, the pressure components will be deformed away from the sealing surface, and the seal will fail. Double sealing eccentric ball valve has two sets of eccentric sealing surface, whether the valve withstands forward or reverse pressure, the deformation of pressure components will always work on one sealing surface, Therefore, this valve is particularly suitable for systems that require bi-direction strict closing.

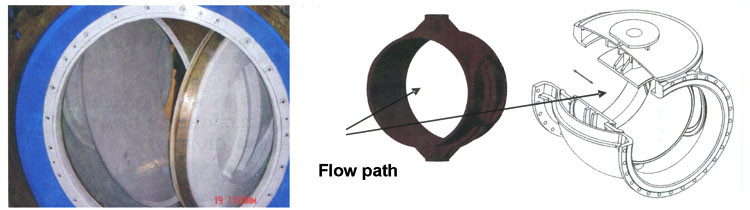

Two sets of sealing surface are eccentric structure: There is eccentricity between valve core rotation center and sealing surface center line, the valve is closing, the valve will be closed more and more tighter, when valve core turned a small angle, sealing surfaces will quickly disengage, sealing surfaces will not wear, service life is long.

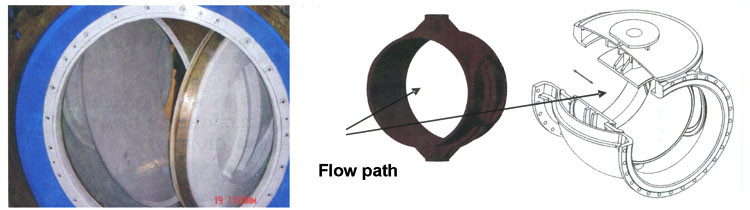

Sealing surface can easily cut off weeds, branches and other fibrous or rod-shaped debris, dust, sediment, scale and other dirt which deposited in the sealing surface. Each time the valve is opened or closed, the sealing surface can be self-cleaned.

2,Adopts full bore straight structure flow path, when valve is fully open, valve flow path is equal to a full diameter straight pipe, flow rate is high, suitable for working environment with high flow rate and easy to produce cavitation damage, flow resistance is small, can save a lot of energy.

3,Double sealing surface eccentric ball valve has a simple structure and does not need maintenance when working. When inspection and repairing, the valve does not need to be removed from the pipeline, just open the bonnet, you can remove valve core, sealing surface from the valve body. Sealing surface and packing can be replaced with pressure.

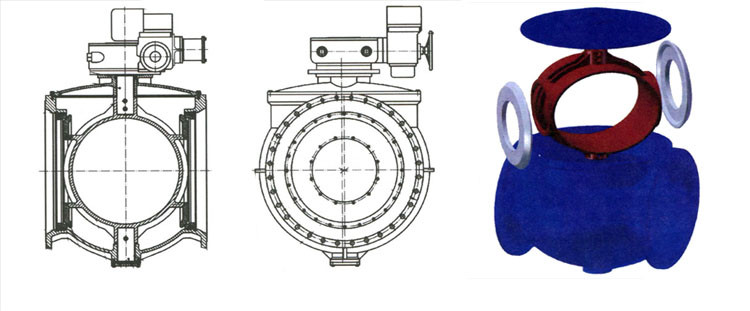

4,Can be used as water seal gas cut-off valve (or other flammable, explosive, toxic gas shut-off valve)

In the steel gas system, normally need to use valve to cut off the pipeline, requiring the valve outlet gas leakage is absolutely zero, to ensure safety. Generally, goggle valve or slide valve will be used. Goggle valve and slide valve have two major shortcomings First, need to release clamping mechanism when opening and closing, gas leakage may occur,have strict requirement for site protection Second, the valve is bulky and heavy, take up large space, when opening and closing, the operating procedures is complex.

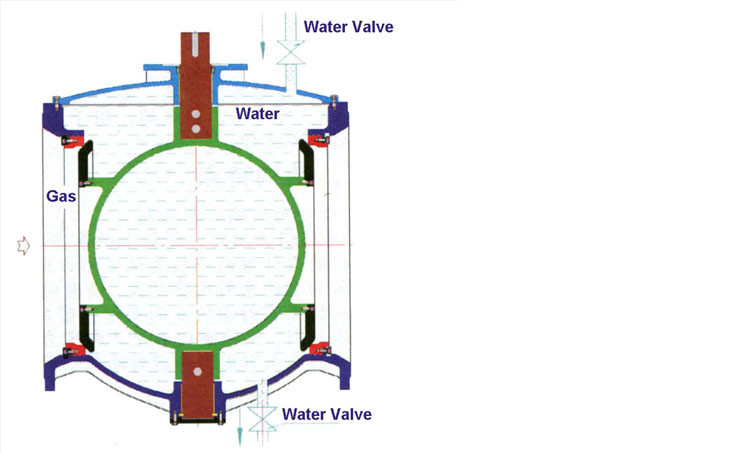

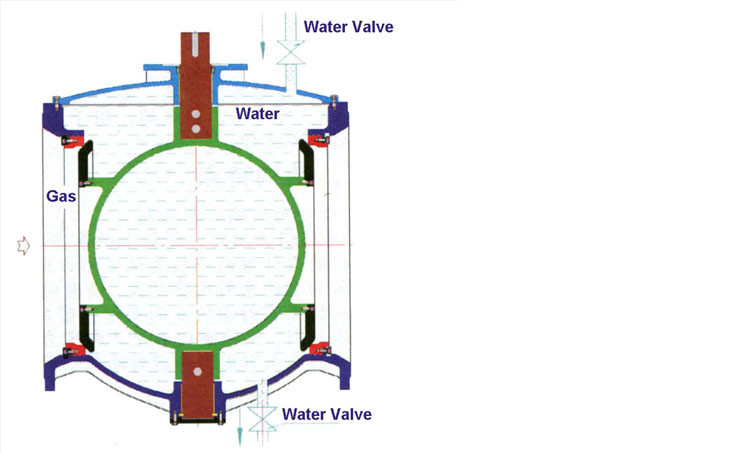

5,When double sealing surface eccentric semi ball valve works as a gas cut-off valve, we only need to install DN50 water valves at both the top and the bottom. After gas cut-off valve closed, fill tap water into valve chamber via water valves (Pressure should be more than 0.5MPa), water sealing will be formed in valve chamber. When there is few gas leakage in valve inlet, gas will dissolve into the water. Even if the valve is closed for a long time, the gas leaked into the valve chamber is more, because the gas density is much smaller than water, it can only accumulate in the water at the top, never break through the water seal. So leakage of the gas cut-off valve is zero. Before opening gas cut off valve, open water valve to discharge the water in valve chamber firstly, small amount of gas can be discharged together with water. Valve core turns 90 0 to complete opening or closing, simple and quick operation.

Work As Water Seal Gas Cut-off Valve: